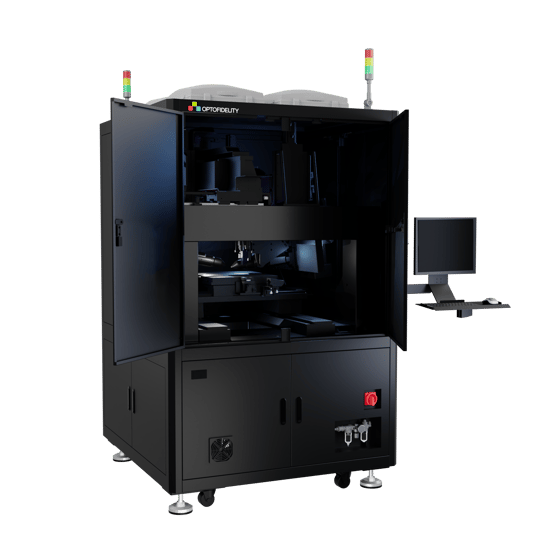

OptoFidelity Production MTF

High-Resolution Automated AR Waveguide Image Quality Measurement System

Traceable & Scalable Quality Assurance for AR Manufacturing

OptoFidelity Production MTF is part of the OptoFidelity Production Family, a set of automated waveguide measurement testers for AR waveguide manufacturing. The Production Family testers bring traceability, repeatability, and scalability, revolutionizing AR quality assurance.

High-Resolution Automated Waveguide Image Quality Measurement System

OptoFidelity Production MTF is a high-resolution Modulation Transfer Function (MTF) and Chief Ray Angle (CRA) automated tester designed to enhance quality control in AR waveguide manufacturing. Tailored for precision and speed, it ensures superior product performance at every stage of the manufacturing process.

The Production MTF quantifies the waveguide’s ability to transfer detail levels from object to image, measured by contrast (degrees of grey) over different spatial frequencies. It also measures the angular change of the principal ray when it passes through the waveguide display, which could be used to detect chromatic aberrations.

Advanced Waveguide Testing with OptoFidelity's OptoEye MTF

Production MTF uses OptoFidelity’s OptoEye MTF – a unique, cost-efficient, diffraction-limited optical instrument offering a wider field of view than any existing solutions in the market while providing sufficient resolution.

The Production MTF quantifies the waveguide’s ability to transfer detail levels from object to image, measured by contrast (degrees of grey) over different spatial frequencies. It also measures the angular change of the principal ray when it passes through the waveguide display, which could be used to detect chromatic aberrations.

Production MTF Benefits

Key features and benefits of Production MTFMTF Measurement

Evaluate the waveguide's ability to transfer image detail with high contrast and clarity, ensuring superior image quality and sharper visual performance of your waveguides. It offers a higher resolution than existing solutions.

CRA measurement

Evaluates how much the angle of light changes when it travels through the waveguide. Ensures monitoring of potential changes in the grating during the manufacturing process.

Reflection (mirror) capability

Enables measurements for waveguide displays with same-side incoupling and outcoupling, currently popular in the consumer market.

Automated, traceable, and scalable measurement system

Offers unique, off-the-shelf volume metrology for AR waveguides. This ensures a robust, stable, and automated quality control for waveguide mass manufacturing.

Integrable to automated handlers

Enables efficient, high-throughput manufacturing processes with consistent quality and reduced manual intervention.

Integrable to customer’s manufacturing line (SEMI-S2, Cleanroom Class 1000)

Designed to meet industry safety standards and cleanroom requirements, allowing incorporation into existing production environments.