News

OptoFidelity Launches Production MTF Advancing Quality Control for AR Waveguide Manufacturing

Production MTF is A High-Resolution Modulation Transfer Function (MTF) and Chief Ray Angle (CRA) Measurement System Designed for Precision and Speed

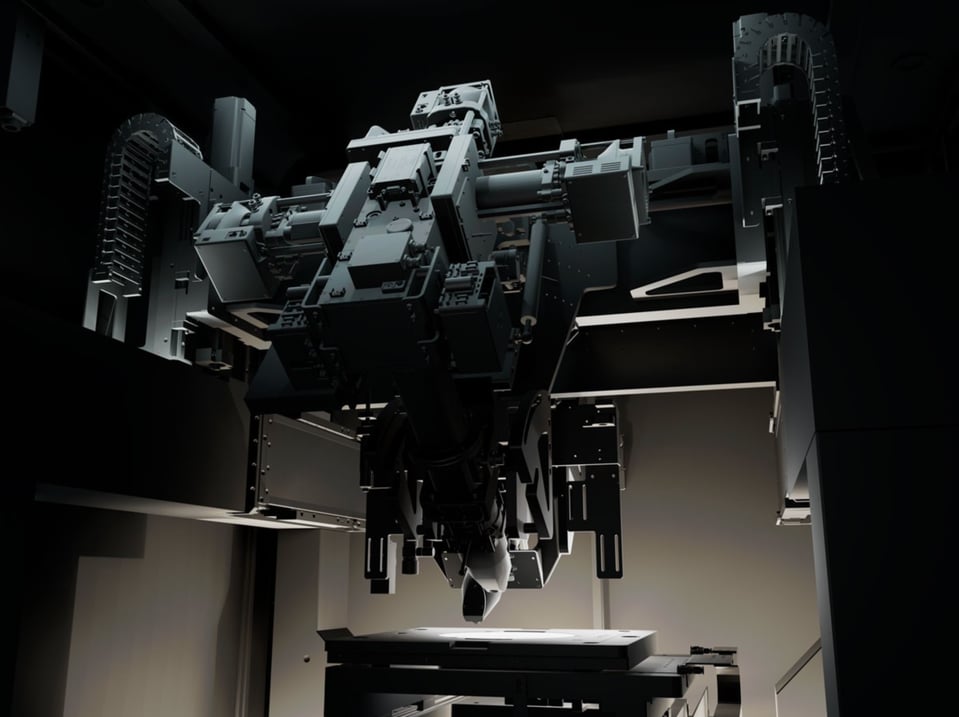

OptoFidelity has launched Production MTF, the latest addition to the OptoFidelity Production Family—a suite of automated waveguide measurement testers designed specifically for augmented reality (AR) waveguide manufacturing. OptoFidelity Production MTF is a high-resolution Modulation Transfer Function (MTF) and Chief Ray Angle (CRA) automated tester designed to enhance quality control in AR waveguide manufacturing. Tailored for precision and speed, it ensures superior product performance at every stage of the manufacturing process.

Joonas Pylväinen, Product Manager of Production MTF said, "We’re excited to expand the selection of Production Family tools with this new waveguide display MTF and CRA measurement system. It brings a fresh set of capabilities to the Family, giving manufacturers more options to configure the system to their specific needs. This new testing system builds on the core idea of modularity and scalability in the Production Family, offering essential tools for waveguide quality control while adapting seamlessly to different line configurations."

OptoFidelity Production MTF is the second offering in our Production family for the manufacturing of waveguides. It is designed to improve quality control in AR manufacturing.

Key Features and Benefits

MTF measurement: Evaluate the waveguide's ability to transfer image detail with high contrast and clarity, ensuring superior image quality and sharper visual performance of your waveguides.

CRA measurement: Evaluates how much the angle of light changes when it travels through the waveguide. Ensures monitoring of potential changes in the grating during the manufacturing process.

Reflection (mirror) capability: Enables measurements for waveguide displays with same-side incoupling and outcoupling, currently popular in the consumer market.

Automated, traceable, and saleable measurement system: Offers unique, off-the-shelf volume metrology for AR waveguides. This ensures a robust, stable, and automated quality control for waveguide mass manufacturing.

Integrable to automated handlers: Enables efficient, high-throughput manufacturing processes with consistent quality and reduced manual intervention.

Integrable to customer’s manufacturing line (for example, SEMI-S2, Cleanroom Class 1000): Designed to meet industry safety standards and cleanroom requirements, allowing incorporation into existing production environments.

Written by