Blogs

Measuring Human Touch

We at OptoFidelity are enthusiastic about the accuracy of our test and measurement systems. In order to pursue the highest possible accuracy and repeatability, we have integrated several technologies into the TOUCH test system, such as purpose-built mechanics, linear motors, multi-axis synchronized motion, machine vision-based positioning, robot calibration methods, and camera calibrations.

During a related technology discussion, we started to contemplate how accurately our touch system engineers can touch things. Or in other words, what is the human spatial accuracy when making touch gestures? We decided to conduct an experiment to study this.

The coffee break TOUCH challenge 20 x 20 tap test!

We wrote a tiny Android app to enable an empirical study of our engineers. The app shows a dot at a random location on the display and waits for the user to tap it. For each tap, the app compares the absolute location of the dot and the location of the human tap.

App functionality:

- Only one dot is visible at a time.

- The location of the next dot is always different from the previous one.

- The dots are in the center area of the screen, as the smartphone touch sensors are typically the most accurate in this area.

- A total of 20 dots will be displayed for each person.

Rules of the challenge:

- Human touch only - no robotics, styluses or wrist supports allowed!

- Tap the way you would use the touch UI in regular use - however, try to tap accurately.

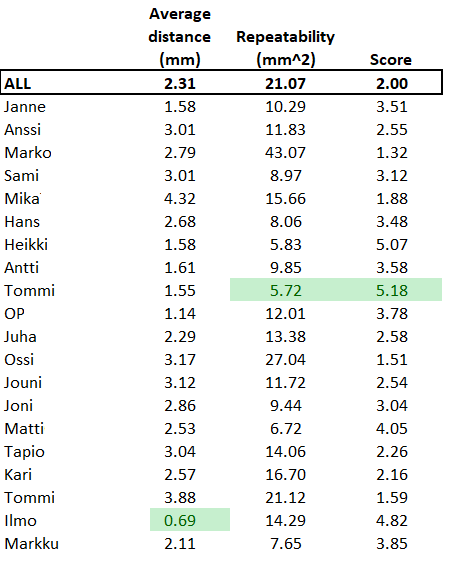

- Accuracy (mm) = average distance between the target dot and the actual tap location (the smaller the distance, the better the accuracy)

- Repeatability (mm^2) = area of the tap gesture locations with 95% confidence level (the smaller the area, the better the repeatability)

- Score = overall performance score, calculated as distance result/distance ALL + repeatability result/repeatability ALL (the higher the better)

Results

We found two exceptionally accurate individuals in our engineering team. One of them excelled in accuracy, the other in repeatability. The human (in)accuracy is a result of parallax, visual acuity and the speed of the feedback loop between the eyes and the fingers. However, the relative precision of the human finger alone is much higher than this, when assistive technologies are provided and the test is done in a controlled environment.

In our fast-paced test, the results indicated the following:

- Average Accuracy: 2.3 mm

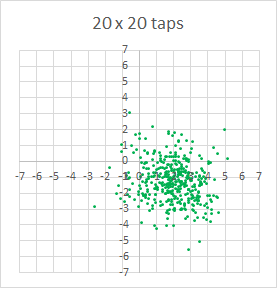

- There is a visible bias of touch location to the right as compared to the left of the target (all test participants were right-handed).

- Average Repeatability: 21.1 mm^2

- Some people had high average accuracy, but touches scattered when measured by repeatability.

Chart 1: Group results

Chart 2: Scatter chart of all 400 taps

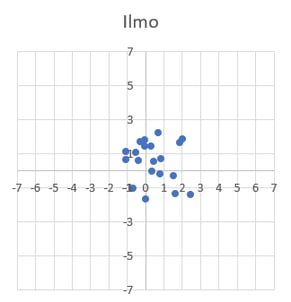

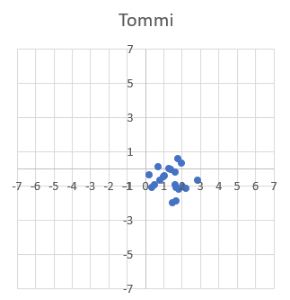

Charts 3 and 4: Personal best touches; repeatability vs. accuracy

Huawei P10 accuracy and repeatability measured with OptoFidelity TOUCH

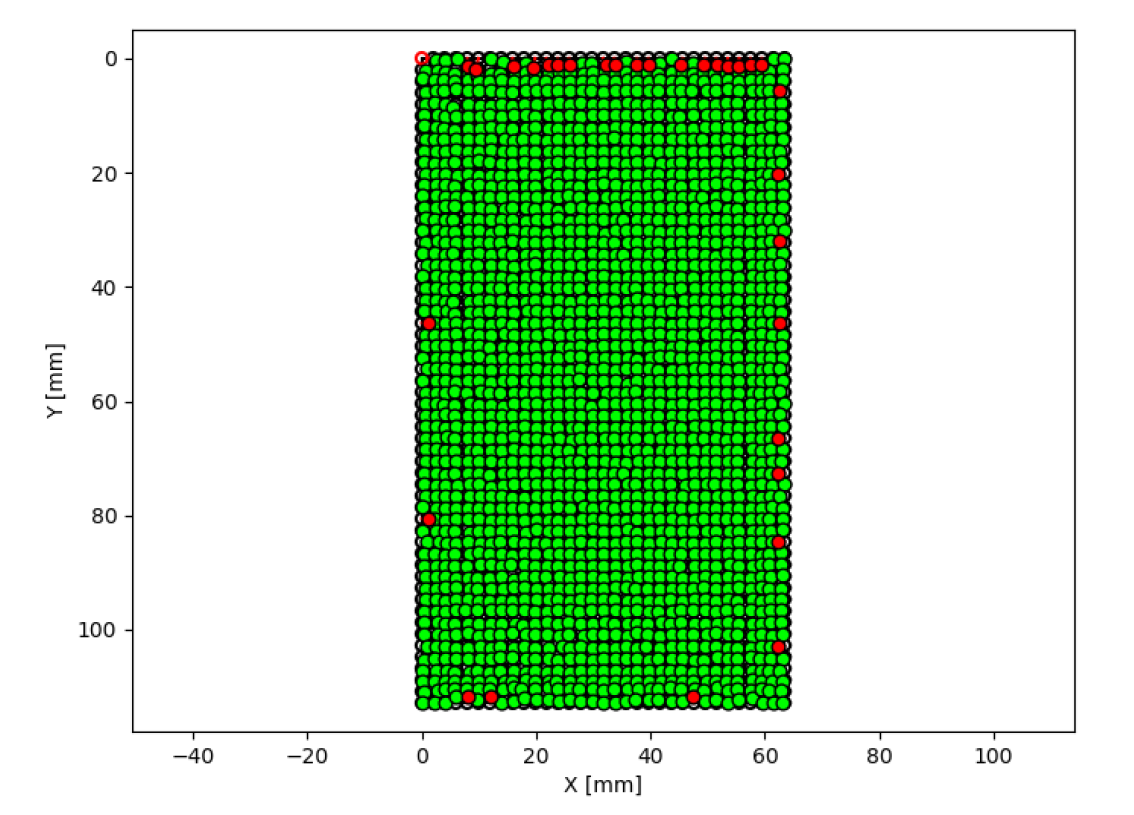

We also wanted to check the baseline accuracy of the Huawei P10 we used for the experiment with the OptoFidelity TOUCH test system. The test configuration used was the standard Tap Test with 2 mm grid (visualized below).A Flat-head brass fingertip with 7 mm finger was used for this characterization.

Chart 5: Test configuration

Chart 5: Test configuration

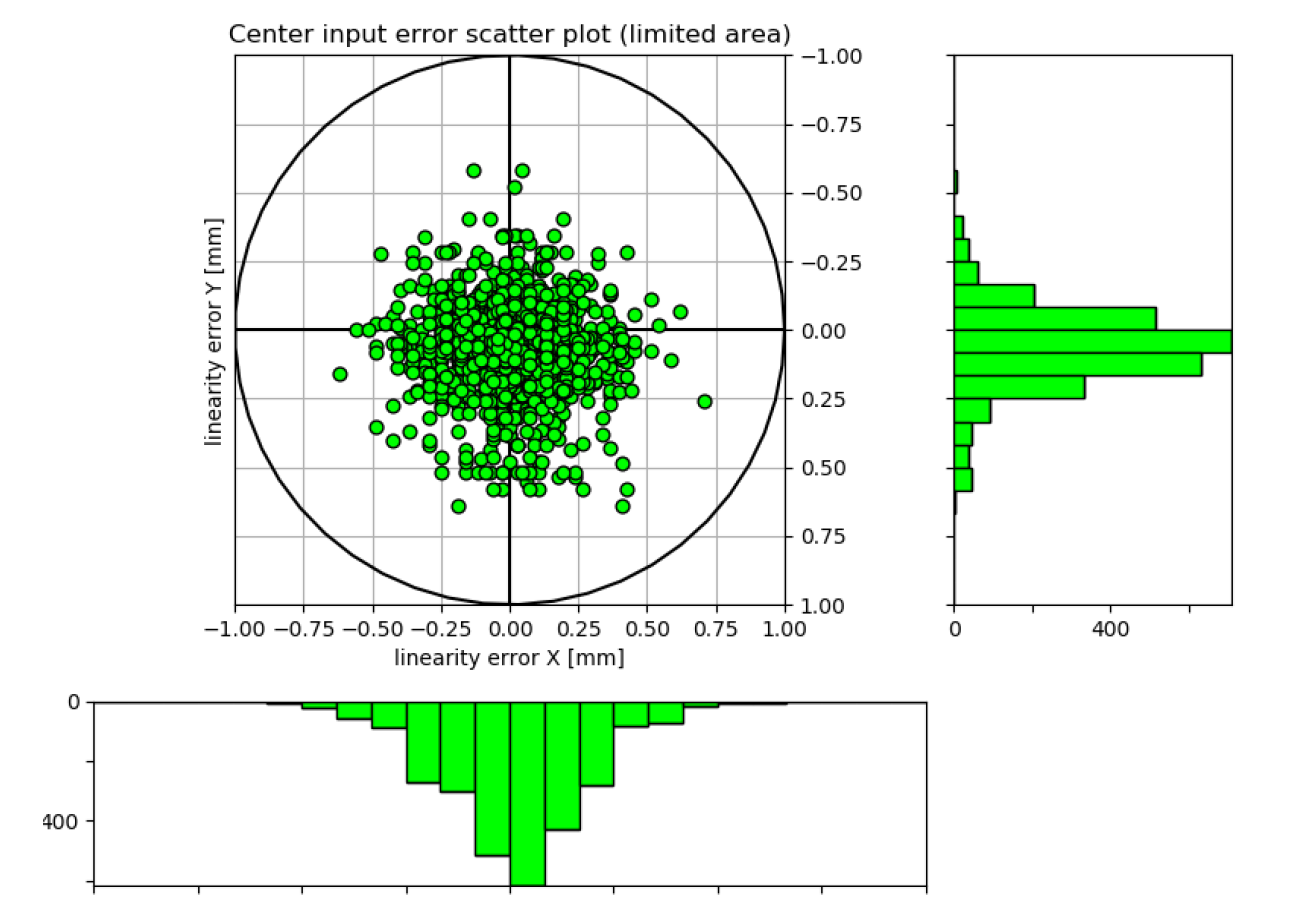

Chart 7: Huawei P10 center area accuracy scatter chart.

These results are very good and comparable with other high-end smartphones on the market.

Why is touch testing important?

Shipping a device with poor touch accuracy will significantly impact the perceived performance and the quality of the device, as well as the brand of the manufacturer. The following aspects affect touch performance and need to be taken into account in the R&D phase of the product life cycle.

- Product hardware integration and packaging

- Characteristics of the selected touch panel

- Touch controller configuration and tune

- Operating system

- User Interface design and layout

In the manufacturing phase, the variations in the manufacturing process create a need for ensuring consistent product quality.

In conclusion, human touch accuracy is not that great. This appears to be true even for seasoned touch test experts. Poor implementation of touch hardware and software emphasized the spatial error already present in touch events. Other important factors are the graphical design of the touch UI, the size of the screen, environmental aspects like being indoors/outdoors, as well as rain and cold temperature. Measuring the touch performance in every phase of the product development cycle helps to create an excellent user experience.

A typical consumer device needs to support at a minimum +/- 1 mm touch accuracy. To achieve repeatable and reliable measurement results, the measurement system needs to be 10 times more accurate than the touchscreen under testing. This translates into a touch test system accuracy minimum of +/- 0.1 mm.

About OptoFidelity TOUCH

The OptoFidelity TOUCH test system and its predecessors have been used for touch UI testing and measurement needs for over ten years. For test system accuracy, OptoFidelity TOUCH systems are validated for their motion accuracy using an external absolute interferometer with a +/- 25 μm measurement accuracy. Currently, TOUCH test systems are in wide use in product R&D and manufacturing with an installed base of 1,000+ systems. Customers benefit from a convenient and easy-to-control system, including a scripting API with a range of touch gestures and gesture control in device coordinates. In addition to the accuracy tests, the TOUCH test system supports other equally important touch UI tests including linearity, repeatability, reporting rate, and jitter. Based on the testing needs, the system is provided with the capability to make one-finger, two-finger and multi-finger tests.

Written by