Blogs

Haptic Testing Explained: Measuring Touch Feedback for Devices

What is Haptic testing?

Haptic testing is more than just touch testing - Haptic feedback is what the user feels when operating a device. Haptic testing has to evaluate the feedback a user gets when interacting with a device. Imagine pressing a mechanical switch: when you press down, you don’t just see the action on screen, you actually feel a click in your fingertip. This physical sensation, or "haptic feedback" confirms that the input has been registered, which is especially valuable in touch-sensitive areas like automotive interfaces, where users rely on this feedback to know their commands have gone through.

This tactile feedback is a critical element of haptic testing because it directly impacts the end-user experience. When the feedback feels intuitive and responsive, users feel more confident and connected to the device.

Haptic feedback has become a vital feature in various consumer and automotive devices, enhancing user experience by providing tactile confirmation of interactions. The most common applications include:

Haptic feedback has become a vital feature in various consumer and automotive devices, enhancing user experience by providing tactile confirmation of interactions. The most common applications include:

- Smartphones: Haptic feedback in smartphones offers users a subtle vibration when they tap on the screen, type on a virtual keyboard, or interact with specific features, improving responsiveness and user engagement.

- Laptops (Trackpads): Many laptops now feature haptic-enabled trackpads that give a "click" sensation without an actual mechanical click. This haptic feedback ensures a consistent feel across the entire trackpad surface, improving usability and making interactions feel more intuitive.

- Automotive Displays: Haptic feedback is becoming more prevalent in car dashboards, where touch-sensitive displays allow drivers to interact with various controls. The tactile response provides reassurance that the command has been registered, making interactions safer and more efficient by reducing the need for drivers to take their eyes off the road.

As these industries continue to innovate, haptic feedback will likely expand to more devices, underlining the importance of precise and reliable haptic testing solutions.

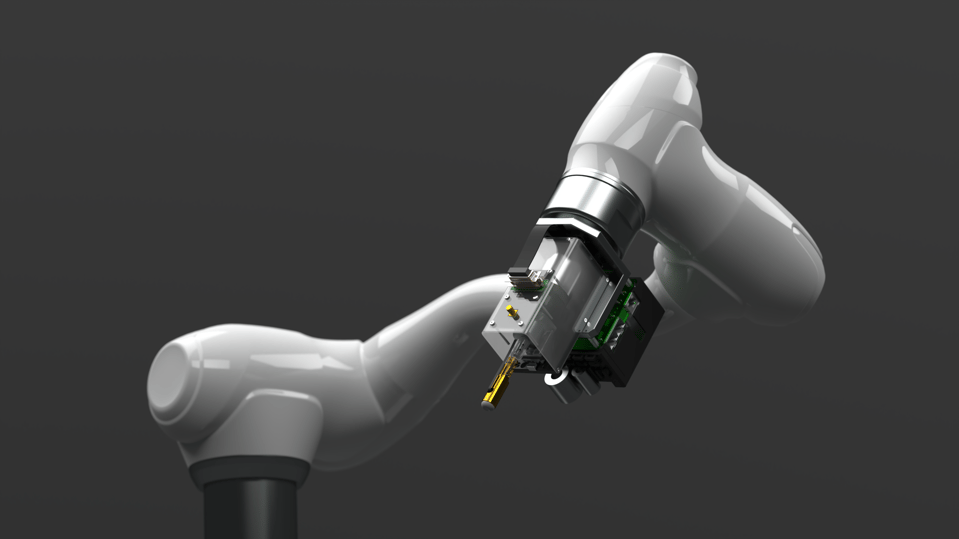

How does our Haptic Tester work?

Our haptic tester assesses how a Device Under Test (DUT) vibrates and responds when pressed with a specific force. Essentially, it measures the device’s tactile feedback, or "haptic response," which users feel as they interact with the device. Our tester performs a Press and Release haptic event measurements of the device measuring both steps

When we press the DUT, the tester captures several key data points from the resulting vibration:

- Amplitude: The strength or intensity of the vibration.

- Direction: The exact path or orientation of the vibration.

- Frequency: The rate or speed of the vibration response.

- Duration: The length of time the vibration lasts.

Additionally, we measure the amount of force applied to the device's surface - an important metric in research and development (R&D). This enables manufacturers to confirm that the device only delivers feedback when pressed with the intended amount of force, ensuring consistency and reliability in user interactions.

The data gathered by our haptic tester provides manufacturers with insights into the quality of their device’s haptic feedback. By analyzing these measurements, they can determine if the tactile experience meets their standards and identify areas for refinement in both the design and functionality of the device.

Why is measuring Haptics so important?

Haptic technology is an evolving field, and precision in measuring haptic responses is crucial for manufacturers aiming to deliver a consistent and reliable tactile experience. Currently, our haptic tester plays a key role in the research and development (R&D) phase of product creation, allowing engineers to validate that their designs provide the intended response. By capturing and analyzing the device's feedback, R&D teams can make fine adjustments to the haptic parameters, verify these changes, and ensure the haptic feedback aligns with user expectations. This validation process is essential, particularly as haptic technology becomes more sophisticated.

Use Case Laptop Trackpad

For instance, let’s consider a laptop's trackpad. A trackpad often consists of multiple haptic actuators that needs to work together to ensure consistent feedback across the entire surface.

Manufacturers rely on precise measurement tools to verify that each of these actuators responds uniformly, regardless of where the user touches it. The haptic tester measures the force, direction, amplitude, and duration of each response to confirm that users feel the same feedback whether they touch the top left or bottom right corner of the trackpad.

Reliability and accuracy are of high importance to our customers, as inconsistent or unreliable feedback can compromise user satisfaction. Any variability in the haptic actuators- whether due to issues in the assembly process, the quality of materials, or other manufacturing discrepancies - can directly impact the device's perceived quality. Our haptic tester addresses this challenge by providing manufacturers with a standardized, dependable solution. This ensures that each contract manufacturer can apply a uniform haptic testing process, maintaining consistent quality across production batches.

While the haptic tester is currently most beneficial in the R&D phase, it also offers the potential for use in mass production as haptic technology advances. Having a standardized, reliable haptic testing solution is especially valuable as companies move toward scaling up, ensuring every device performs as intended right from the first production run.

Behind the Scenes: What makes measuring Haptics so complex, and how do we do it?

Measuring haptics is a complex area because it involves the integration of multiple specialized technologies. To accurately capture the subtle vibrations and feedback that define a device’s haptic response, our haptic tester must seamlessly combine mechanical engineering, sensor technology, electronics, and advanced software.

- Mechanical Structure: The measurement tip itself must be precisely designed to detect even the slightest vibrations when in contact with the DUT without dampening the haptic responses on different directions. This tip's mechanical structure is crucial, as it directly influences the accuracy of the vibration sensing.

- Advanced Sensor Technology: Embedded within the tip is sensor technology capable of capturing fine details of the haptic feedback, such as amplitude, direction, and frequency. These sensors must be sensitive and precise enough to distinguish between minor variations in vibration, ensuring consistent and accurate results.

- Electronics and Software: Specialized electronics and sophisticated software are required to process and analyze the raw data collected by the sensors. The software interprets this data, calculating key metrics and translating them into meaningful feedback that manufacturers can use to assess and refine their products.

This complexity is a significant barrier to entry, and it sets our haptic tester apart. We integrate all of these technologies into a single, streamlined instrument, making our solution uniquely capable of providing comprehensive, reliable haptic measurements. By mastering these combined technologies, we enable manufacturers to understand and perfect the haptic performance of their devices thoroughly.

Contact us now and read more about our Haptic tester on our Haptic page.

Written by