Blogs

BUDDY – The Forerunner of Temporal Characteristics Measurement for AR/VR Headsets

You may have seen our BUDDY robot at the exhibitions and in our marketing content. But what is the story behind the robot? Read about our development and what drives us further to enable a smarter future.

BUDDY's story goes back to 2016 when OptoFidelity produced the first Motion-to-photon (MTP) latency tester for mobile phones. In the tester, a phone would be standing on its side on a rotating stage, screen towards an 8x8 pixel camera. Beneath the manually rotated stage, an encoder was located. OptoFildelity's own Android VR application was installed on the phone and the synchronization of the camera triggering and phone refresh rate was done with a separate fiber connection. The position analysis and MTP latency were calculated by OptoFidelity Video Multimeter with the information from the encoder data and the camera image. Together the rotating stage and the Video Multimeter formed a tester which back then was called OptoFidelity VR Multimeter.

Already during 2016, the first requests for a temporal tester for VR HMDs came in. As an answer to requests, the VR Multimeter was upgraded with a human-like head which was mounted on top of the previous model's rotational stage. The stage was upgraded from manually operated to stepper motor operated. The tester still bore the name VR Multimeter and it was launched in 2017.

2017 brought a change in camera technology too. The purposely built OptoFidelity Smart Camera with VGA resolution would eventually take the role of identifying and calculating the constellation markers in the VR content.

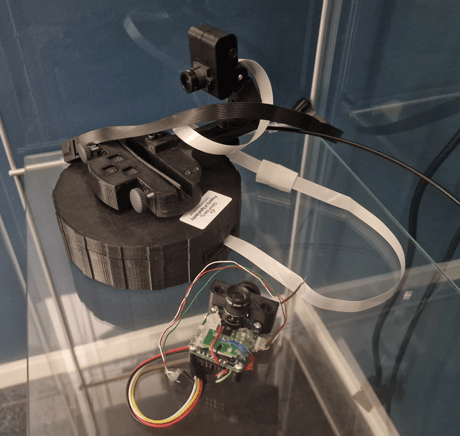

Quite evidently the one degree of freedom (one rotational axis) wasn't going to be sufficient for long and therefore in 2018, a gimbal was introduced to the tester, allowing all rotational degrees of freedom: yaw, pitch, and roll. The BUDDY was born.

2018 BUDDY with 3DOF gimbal

BUDDY could detect refresh rate and pixel persistence and conduct measurements and analysis of stationary jitter, drifting, tracking repeatability, and motion-to-photon latency, in all three rotational axes. The movement prediction overshoot and undershoot could be studied from the UI-provided graphs where the movement lines in the real world and the virtual world would be seen in the same coordinate system. These groundbreaking features allowed AR/VR HMD manufacturers to develop and tune their products to a level where latency and jitter-generated motion sickness could be drastically reduced. The automated test procedure could now be used instead of subjective human tests where results could differ even based on the time of day.

In 2020 the camera was upgraded again, this time to a 3.1 Mpx camera.

-png.png?width=2278&height=877&name=MicrosoftTeams-image%20(11)-png.png)

2020 BUDDY 3DOF wearing different helmets and headsets

In 2022 BUDDY received additional 3 degrees of freedom (X, Y, Z linear axes), allowing movement in all six axes.

Together with the additional degrees of freedom, an ability to measure see-through latency and hand-controller motion tracking was introduced.

2022 BUDDY 6DOF with added XYZ-stage

OptoFidelity is leading the design and manufacture of automated test systems for the AR/VR/MR market. BUDDY with its patented technologies has been serving customers since 2017. It is one of its kind in AR and VR HMD performance testing. BUDDY’s precision robotics accurately model human movement while gathering data on the tracking performance of AR/VR glasses. With its 6DOF (six degrees of freedom), BUDDY puts you ahead of the curve early in HMD product development.

Did you get interested in hearing more? Contact us today and we are happy to guide you further.

Written by