Mastering AR Waveguide Grating Quality with Littrow Diffractometers

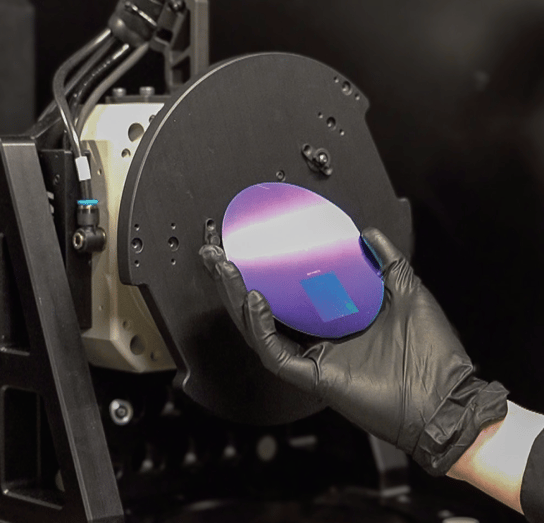

In the manufacturing of diffractive waveguides, grating quality means measuring all critical dimensions of the diffraction grating profile. It includes the grating period (pitch) and relative orientation of the grating areas on the waveguide layout, which significantly impacts the display unit function.

For most AR waveguide designs, the tolerance for the grating period is on the scale of a few tens of picometers, and for grating orientation, it is on the scale of a few tens of arcseconds. Techniques such as Scanning Electron Microscopy (SEM) and Atomic Force Microscopy (AFM), while valuable, have limitations in discerning and quantifying these essential grating quality attributes at the level required by the AR industry.

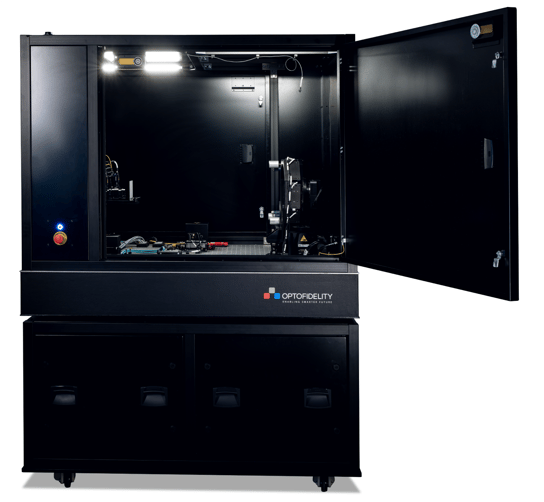

Enter the Littrow diffractometer and OptoFidelity’s WG-GAT system.

Key Points of This Use Case

-

The assessment of grating quality plays a crucial role in the development of AR waveguides.

-

Littrow diffractometry offers the precision and reliability required to test diffractive waveguide gratings, making it indispensable for the future of augmented reality device development and production.

-

OptoFidelity’s Littrow Diffractometer WG-GAT has emerged as a game-changing solution for this need.

How Do AR Displays Work?

The most common solution for AR displays are diffractive waveguides. This is how they work:

The Exit pupil of a projector unit is placed on the surface of a glass plate to project light into a diffraction grating, often referred to as in-coupler grating. The grating diffracts the light at a large enough angle such that it is trapped inside the glass waveguide due to total internal reflection. One or two additional gratings are then used to gradually extract the light, making displaced copies of the exit pupil, often referred to as exit pupil expansion.

As a result, the user gets a large eye box, allowing the human eye to be in various locations while still being able to see the AR display content. The main benefit is that this enables the same AR display to be suitable for a wide range of users with varying interpupillary distances or facial topology.

Characterizing Diffractive Waveguide Gratings

When the beam of light hits the diffractive grating, it is split into multiple diffraction orders that spread in different directions predictably according to the diffraction equation. The diffraction phenomenon occurs on a plane perpendicular to diffraction grating lines.

The grating structure spacing, or line spacing, known as the pitch or period of the grating, dictates the output angle of the diffraction orders. The efficiency of each diffraction order depends on, among other factors, the shape and the height of the grating cross-sectional profile.

In AR Displays, it is essential that the gratings are adequately uniform and manufactured with sufficient precision to enable high image quality to be projected to the users’ eyes. Here, it is crucial that the grating quality can be characterized.

The Challenge When Characterizing Waveguide Gratings

Characterizing the grating is a challenge because the dimensions of the diffractive waveguide gratings can be smaller than the wavelength of visible light. For example, optical microscopy cannot resolve the features of AR waveguide gratings accurately.

Period and Orientation Measurements

The key parameter for AR displays is the direction of the diffracted light, which is only affected by the grating period and orientation, not by, for example, the height deviations of the grating profile. To characterize these properties, it is enough to measure the diffraction angle of a single diffraction order with a monochrome light source. This method can characterize both transmissive and reflective gratings.

What’s needed for this technique are a light source, a detector, and a way to measure the angles between the sample, light source, and detector. Here, the Littrow Diffractometers come into use. The required tolerances for the grating periods can be surprisingly strict (in order of picometers) because light propagates a relatively long distance into the waveguide, experiencing multiple total internal reflections at once. Also, the relative orientations of gratings must be known to a high degree of certainty to guide the light within the waveguide in the correct direction.

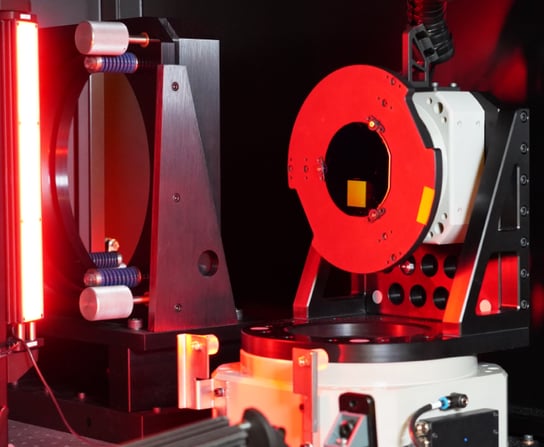

The Solution is to use the Littrow configuration, where the grating sample is rotated so that the wanted diffraction order is reflected back to the light source. A beam splitter can then be used to steer the diffracted beam onto a detector. Utilizing the Littrow equation, when the sample angle, light source wavelength, and diffraction order are known, the grating period can be calculated. Also, the grating line orientation can be determined by the same measurement by introducing another axis or sample rotation.

In order to reach picometer and arcsecond scale performance, there are a variety of measurement uncertainties that must be eliminated to the extremities of calculating the effect of ambient air conditions on the measurement.

Adapting to our customers’ requirements, OptoFidelity is capable of fulfilling the rigorous demands described above and has the expertise to deliver complete grating testing systems. We have the needed high period and orientation measurement accuracy with our Littrow Diffractometer, WG-GAT.

The Benefits of Littrow Diffractometers

-

Preserving AR Grating Integrity

Littrow diffractometers are non-destructive by default. They employ a laser beam to assess the grating quality without physically contacting the sample. With this, it is ensured that the AR grating's integrity is maintained.

-

Real-Time Optical Performance Assessments

For AR Applications it is important to obtain real-time, in-situ measurements of the grating's optical performance. Littrow diffractometers analyze the diffraction pattern produced by the AR grating, offering immediate and accurate information without further analysis needed.

-

Adaptable Wavelength Range for AR Applications

Littrow diffractometers enable easy light source wavelength alternatives to match the AR grating's specific requirements. This adaptability allows for the accurate measurement of AR gratings designed for diverse applications.

-

Consistency and Precision for AR Grating Measurements

Carefully calibrated and developed Littrow Diffractometers have high resolution, repeatability, reproducibility and accuracy. This ensures precise and consistent measurements even when operated by different users or when evaluating multiple AR grating samples. Littrow Diffractometers can measure gratings with an accuracy that is multiple orders of magnitudes smaller than the period of the grating it measures.

-

Streamlined Analysis for AR Grating Evaluation

Littrow diffractometers offer simplified operation and minimal sample preparation, making them user-friendly even for those with limited optics experience. In addition, the results obtained are easily interpreted, streamlining the AR grating evaluation process.