%20(1).jpg?width=2000&name=AdobeStock_502462892%20(1)%20(1).jpg)

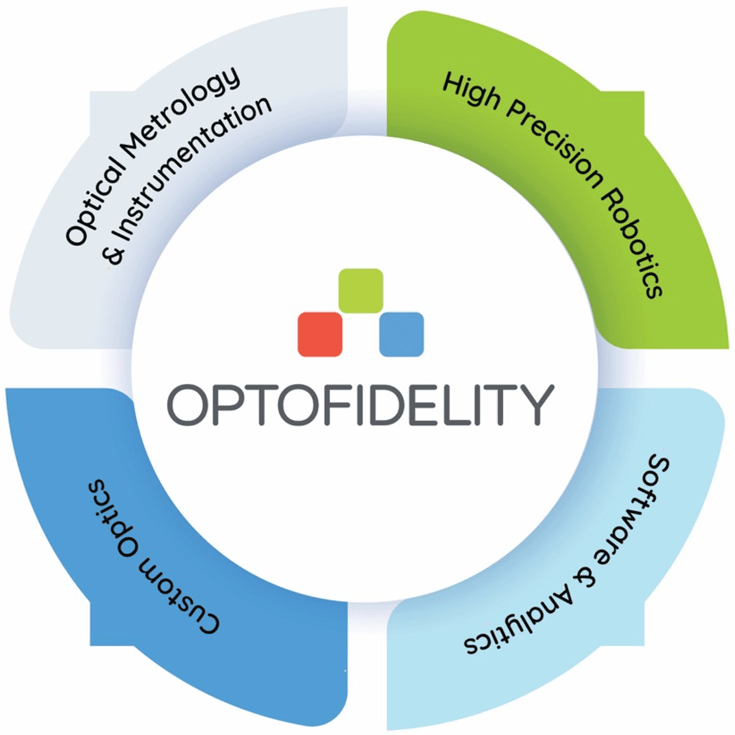

Custom System Integration & Metrology

Tailor-made systems designed to meet individual customer needs with precision and expertise

System Integration & Metrology for Nano-Optics and Smart Electronics

OptoFidelity offers tailor-made test systems designed to meet individual customer needs with precision and expertise.

Our system integration solutions help manufacturers achieve precise metrology and quality control in the R&D and production processes, improving product quality and operational efficiency.

With a long experience and expertise in robotics, optical metrology, custom optics and software development, we are capable to solve highly complex customer challenges.

Designed to meet your needs

Our tailor-made solutions are designed to meet individual customer needs with precision and expertise.

Optical Performance

Customized optical measurement (haze, flare). Customized DUT handling mechanics including motion and robotics for precise positioning.

Nanoscale Critical dimensions measurement

Tracking and latency performance testing for XR glasses

Functional Testing

Tracking and latency performance testing for XR glasses

Use Case Example:

AR Waveguide Grating Characterization

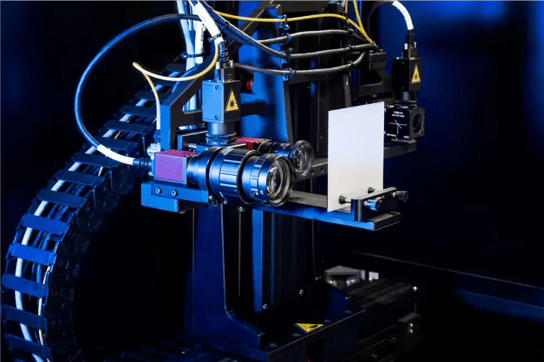

High-Precision, Nanoscale Critical Dimension Analyses enable unmatched accuracy applications

- High-Precision Diffractometer Capabilities:

- Detects grating defects with picometer-level resolution and arcsecond-scale angular precision

- Measures any grating sample, regardless of material or substrate

- Evaluates grating uniformity across extensive areas for consistent performance

Use Case Example:

Tracking and latency performance testing for XR glasses

Functional Testing is valuable for accurate, relevant, reliable performance tests removing human factor from subjective analysis

- End-to-end temporal performance testing and calibration measurement

- Testing of every component that affects the temporal characteristics between motion and photon

- Available in 3- or 6-degrees of freedom

Design

Fast design of custom optics for metrology applications

Prototyping

Fast prototyping of custom optics

Manufacturing

Mass manufacturing capability of custom optics

Alignment and Positioning

Our tools ensure precise alignment by positioning robots or tools accurately relative to the DUT. We enhance robotic system accuracy using advanced machine vision and instruments like laser trackers. Additionally, we calibrate robot positions and movements to compensate for any errors.

Automated Handling

Our automated handling systems manipulate and move DUTs automatically. This enables equipment integration to fully automated manufacturing lines.

Probing

Usage of different tools and sensors to measure or interact with DUT. Probing accuracy in scale of micrometer or nanoseconds.

Use Case Example:

Versatile testing platform for Printed Electronics and Injection Molded Structural Electronics

Comprehensive Testing for Every Step of Production:

- Decoration and Electronics Printing – Ensuring quality and functionality of printed multilayer electronics

- Component Surface Mounting – Verifying surface-mounted electronics integrity

- Thermoforming – Measuring performance after material stretching and forming

- Injection Molding – Assessing final part quality and functionality

.png?width=544&name=hapticspage%20(5).png)

Use Case Example:

Haptic Measurement Instrument

Evaluate haptic feedback and tactile sensations

- Precision Sensors

- High-quality sensors capable of accurately detecting and measuring tactile sensations

- Multi-modal Capability

- Capture and analyze various aspects of touch feedback, including force, frequency, and duration, across different surfaces and materials

- Real-time Data Analysis

- Instantaneous processing and interpretation of tactile data to provide immediate insights into touch interactions

- Integration Compatibility

- Seamless integration with existing hardware and software systems for comprehensive data analysis and visualization

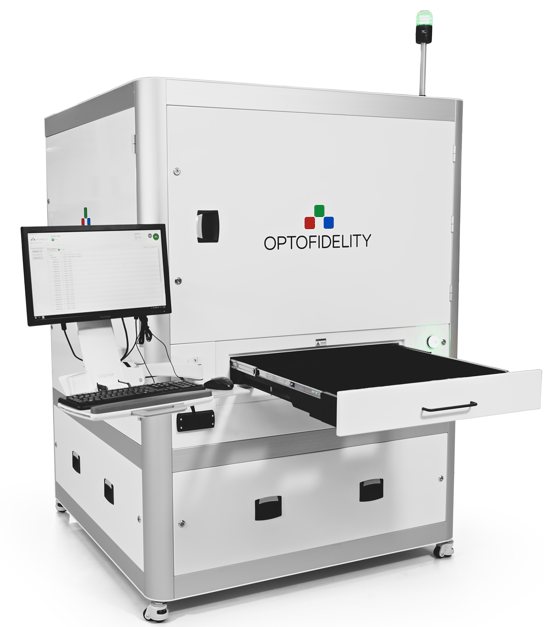

Automated Optical Inspection

Machine vision solutions for visual inspection and precise object handling in automated systems. Full hardware and software solutions.

Data Processing & Analyses

Different analyses based on camera data and other instrument data to verify needed functionality.

Utilizing AI & ML

Utilization of AI and ML techniques to identify and classify objects, and patterns from captured images to separate good and bad units from each other.

Use Case Example:

Objective cosmetic defect detection & grading for pre-owned smartphones

Utilization of AI and ML techniques to identify and classify objects and patterns from captured images to separate good and bad units from each other

- AI-based cosmetic defect detection

- Grading based on customer criteria or standards

- Software & languages

Electrical Testing

Electrical testing refers to testing of DUT electrical functionality according to specification and executing safety measurements like ground bonding and Hipot testing to verify electrical insulation of DUT.

Contact Us

Talk to our experts us to get your tailor-made system designed to meet your needs